Boost Your Business: Improve Operational Efficiency Today

Share

Supercharge Your Operations

Want to improve operational efficiency? This listicle delivers eight proven strategies to optimize your processes and reduce waste. Learn how methods like Lean Management, Six Sigma, and Business Process Automation (BPA) can streamline workflows and boost your bottom line. Whether you're an entrepreneur, teacher, student, or business professional, these concepts are crucial for achieving peak performance. Discover how to improve operational efficiency and gain a competitive edge.

1. Lean Management

Lean management is a powerful methodology for improving operational efficiency by systematically identifying and eliminating waste. Originating from Toyota's Production System (TPS), it focuses on maximizing customer value while minimizing resource consumption. This approach optimizes processes by streamlining workflows and removing any activities that don't directly contribute to delivering value to the customer. Essentially, lean management aims to do more with less.

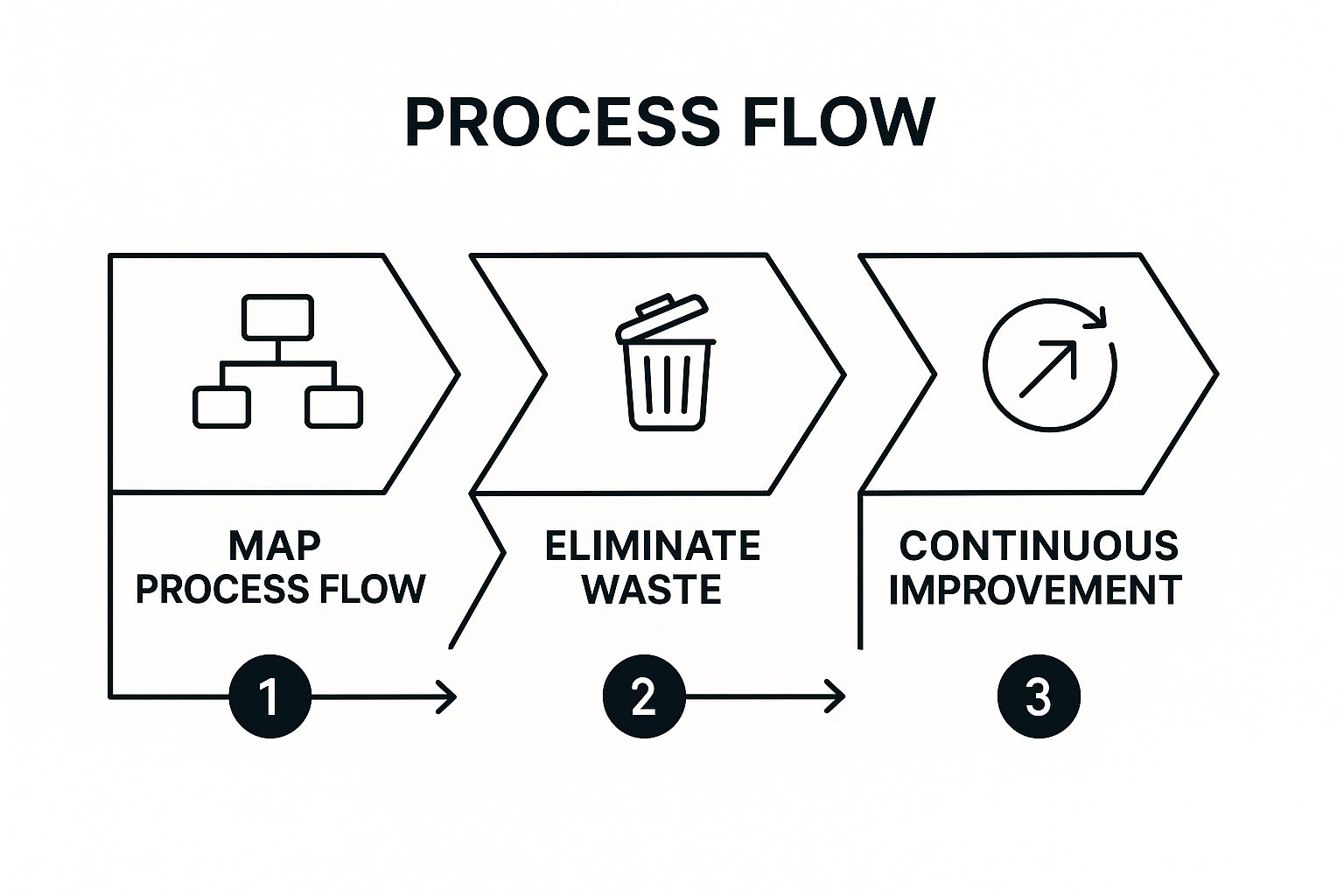

The infographic above illustrates a simplified version of the lean management process flow, visualizing how value is created and how waste is eliminated. The process begins with identifying customer value and then proceeds to map the value stream, highlighting both value-added and non-value-added steps. The next stage involves eliminating the identified waste, followed by implementing a pull system, ensuring flow, seeking perfection through continuous improvement (Kaizen), and finally delivering value to the customer. The cyclical nature emphasizes the importance of continuous improvement and adaptation to changing customer needs. The visualization clearly demonstrates how each step builds on the previous one, ultimately culminating in improved customer value and operational efficiency.

Lean management leverages several key features, including value stream mapping to visually represent and analyze processes, the continuous improvement (Kaizen) philosophy to encourage incremental improvements, just-in-time production and inventory management to minimize storage costs and waste, pull systems (driven by customer demand) rather than push systems (based on forecasts), and error-proofing processes (Poka-Yoke) to prevent defects.

Several success stories demonstrate the effectiveness of lean management across various industries. Toyota's Production System revolutionized manufacturing, becoming a benchmark for efficiency. Virginia Mason Medical Center applied lean principles to healthcare, dramatically reducing patient wait times. Amazon leverages lean principles in its fulfillment centers to optimize order processing, and Kimball International achieved a remarkable 30% productivity improvement through lean initiatives. These examples highlight the versatility and adaptability of lean management principles.

When striving to improve operational efficiency, lean management is particularly valuable when dealing with complex processes, high levels of waste, or customer dissatisfaction. It provides a structured framework for identifying bottlenecks, streamlining workflows, and improving overall performance.

Pros of implementing lean management:

- Reduces operational costs: Eliminating waste translates directly into cost savings.

- Improves quality: Reducing defects enhances product/service quality.

- Enhances customer satisfaction: Faster delivery and higher quality contribute to greater customer satisfaction.

- Creates a culture of continuous improvement: Fosters a proactive approach to problem-solving and process optimization.

- Increases employee engagement: Involving employees in improvement efforts boosts morale and ownership.

Cons of implementing lean management:

- Requires significant cultural change: Shifting to a lean mindset requires buy-in and commitment from all levels of the organization.

- Initial productivity may decrease during the transition: Adjustments and learning curves can temporarily impact productivity.

- Risk of focusing too much on efficiency at the expense of innovation: Overemphasis on efficiency can stifle creativity and innovation.

- Can be challenging to sustain over the long term: Maintaining momentum and continuous improvement requires ongoing effort.

- May require significant training investment: Educating staff on lean principles necessitates dedicated resources.

Actionable tips for implementing lean management:

- Start with a pilot project to demonstrate value and gain buy-in.

- Invest in proper training for all staff levels.

- Focus on customer value first, not just cost-cutting.

- Use visual management tools to make progress visible and transparent.

- Involve employees at all levels in improvement efforts to foster ownership and engagement.

Learn more about Lean Management This resource provides further insights into time management strategies, which can complement lean management principles to enhance overall productivity.

Key figures who popularized lean management include Toyota (TPS - Toyota Production System), James P. Womack and Daniel T. Jones (authors of 'Lean Thinking'), Taiichi Ohno (considered the father of TPS), and Jeffrey Liker (author of 'The Toyota Way'). Their contributions have shaped the development and widespread adoption of lean principles.

2. Six Sigma: A Data-Driven Path to Improve Operational Efficiency

Six Sigma is a powerful methodology designed to improve operational efficiency by systematically reducing process variation and eliminating defects. Its core aim is to achieve a level of quality where processes produce no more than 3.4 defects per million opportunities. This data-driven approach provides organizations with a structured framework for problem-solving and continuous improvement, ultimately boosting efficiency and profitability. For businesses striving to improve operational efficiency, Six Sigma offers a robust set of tools and techniques to achieve significant, measurable results.

How Six Sigma Works:

At the heart of Six Sigma lies the DMAIC cycle – Define, Measure, Analyze, Improve, and Control. This five-phase framework guides the improvement process:

- Define: Clearly articulate the problem, project goals, and customer requirements (Voice of the Customer).

- Measure: Collect data to understand the current state of the process and establish performance baselines.

- Analyze: Identify the root causes of defects and variation within the process.

- Improve: Develop and implement solutions to address the identified root causes.

- Control: Implement control mechanisms to sustain the improvements and prevent regression.

Six Sigma relies heavily on statistical process control and data analysis tools to identify areas for improvement and measure the impact of changes. A key component is its belt-based training system (Yellow Belt, Green Belt, Black Belt, Master Black Belt), which develops internal expertise and ensures consistent application of the methodology.

Why Use Six Sigma to Improve Operational Efficiency?

This methodology is particularly effective when dealing with complex processes that exhibit high variability and defect rates. By systematically analyzing data and addressing the root causes of problems, Six Sigma can lead to dramatic improvements in efficiency, quality, and customer satisfaction. The emphasis on measurable financial returns makes it a compelling approach for organizations looking for tangible results.

Examples of Successful Six Sigma Implementation:

Several prominent organizations have leveraged Six Sigma to achieve remarkable improvements in operational efficiency:

- Motorola: The birthplace of Six Sigma, Motorola saved an estimated $17 billion over 11 years through its implementation.

- General Electric: Under Jack Welch, GE utilized Six Sigma to generate $12 billion in savings over five years.

- Bank of America: By applying Six Sigma principles, Bank of America reduced customer complaints by 10.4% and increased customer satisfaction by 25%.

- Honeywell: This industrial conglomerate achieved $3.5 billion in cumulative savings through Six Sigma initiatives.

Pros:

- Provides a robust statistical framework for problem-solving.

- Creates quantifiable results and demonstrable ROI.

- Reduces process variation and defect rates.

- Improves customer satisfaction through enhanced quality.

- Develops internal expertise through a structured certification program.

Cons:

- Requires significant investment in training and statistical software.

- Can be overly complex for simple problems.

- The highly analytical approach may encounter resistance from some employees.

- The focus on existing processes may, in some cases, limit innovation.

- The certification process can be time-consuming and expensive.

Tips for Successful Implementation:

- Secure executive sponsorship: Leadership support is crucial for driving adoption and resource allocation.

- Select high-impact projects: Focus on areas with clear financial returns and potential for significant improvement.

- Combine with Lean: Integrating Six Sigma with Lean principles can create a more comprehensive approach to operational excellence.

- Invest in proper statistical software and tools: Effective data analysis is essential for successful implementation.

- Celebrate and communicate early wins: Building momentum and demonstrating value early on encourages continued engagement.

By following these tips and embracing the DMAIC framework, organizations can leverage the power of Six Sigma to significantly improve operational efficiency, reduce costs, and enhance customer satisfaction.

3. Business Process Automation (BPA)

Business Process Automation (BPA) is a powerful method for improving operational efficiency by using technology to automate recurring tasks and processes. Instead of relying on manual effort for repetitive, rule-based activities, BPA leverages software and digital transformation tools to streamline operations. This allows employees to redirect their focus towards more strategic, value-added tasks that require human ingenuity and critical thinking, ultimately boosting overall productivity and driving business growth. BPA deserves its place on this list because it offers a significant opportunity to eliminate inefficiencies, reduce costs, and improve accuracy across a wide range of business functions.

BPA encompasses a range of technologies and functionalities, including workflow automation, which digitizes and automates the flow of information between different stages of a process; document digitization and management, which eliminates paper-based processes and improves accessibility; Robotic Process Automation (RPA), which utilizes software robots to mimic human actions for repetitive tasks; integration between various business systems, creating a seamless flow of data and eliminating data silos; and business process analytics and monitoring, providing insights into process performance and identifying areas for further optimization.

The benefits of BPA are substantial. It dramatically reduces human error in routine processes, leading to increased accuracy and improved output quality. It speeds up process execution significantly, allowing businesses to respond to customer needs more quickly and efficiently. By standardizing processes, BPA provides consistent results and improves compliance through automated tracking and documentation. Perhaps most importantly, it frees up human resources, allowing employees to focus on more strategic work, innovation, and problem-solving.

However, implementing BPA also comes with its challenges. Initial implementation costs can be high, involving software licenses, integration efforts, and potentially consulting fees. It may require significant process redesign before automation can be effectively applied. Some employees may resist automation, fearing job loss or disruption to their established routines. Furthermore, BPA can sometimes create inflexibility if business conditions change rapidly, requiring adjustments to the automated systems. Finally, businesses can become dependent on specific technologies or vendors, potentially limiting their options in the future.

Numerous organizations have successfully implemented BPA to achieve remarkable results. UiPath implemented RPA at Coca-Cola to automate order processing, saving 40% of processing time. American Express uses automation to process credit applications, reducing processing time from 7 days to just minutes. Zappos automated their inventory management system to achieve near-perfect order accuracy. Netflix leverages automation in their content delivery systems to optimize streaming efficiency. These examples highlight the transformative potential of BPA across diverse industries.

To successfully implement BPA, consider the following tips: Start by mapping and optimizing processes before automating them to ensure maximum efficiency. Focus on high-volume, rule-based processes first to achieve the greatest impact. Involve end-users in the design and implementation phases to gain buy-in and ensure the solution meets their needs. Plan for change management and employee reskilling to address potential resistance and equip employees for new roles. Finally, build in regular review cycles to identify additional automation opportunities and continuously improve processes. Companies like UiPath, Automation Anywhere, Blue Prism, and ServiceNow are leading the way in providing BPA solutions.

When striving to improve operational efficiency, BPA is a valuable tool to consider. It’s particularly useful when dealing with repetitive, rule-based tasks that consume significant time and resources. By automating these processes, businesses can free up valuable human capital, reduce errors, and accelerate operations. Learn more about Business Process Automation (BPA) and discover how setting SMART goals can help you effectively plan and implement your BPA strategy.

4. Total Quality Management (TQM)

Total Quality Management (TQM) is a powerful approach to improve operational efficiency by fostering a culture of continuous improvement centered around customer satisfaction. Rather than viewing quality as a separate department or function, TQM integrates quality principles into every aspect of an organization, from product development and manufacturing to customer service and administrative processes. This holistic approach aims to achieve long-term success by consistently meeting and exceeding customer expectations.

TQM operates on the principle that every employee, regardless of their role, is responsible for quality outcomes. It emphasizes data-driven decision making, using metrics and customer feedback to identify areas for improvement. By focusing on preventing defects rather than simply detecting them, TQM helps organizations reduce waste, lower costs, and enhance efficiency. It's a system-wide approach that considers the interconnectedness of processes and the impact of each on overall quality. Key features of TQM include:

- Customer-focused approach to quality: TQM prioritizes understanding and meeting customer needs as the foundation for all quality initiatives.

- Continuous improvement methodologies: Methodologies like Plan-Do-Check-Act (PDCA) cycle and Six Sigma are often integrated within a TQM framework to drive ongoing improvement efforts.

- Organization-wide participation in quality initiatives: TQM requires the active involvement of all employees, fostering a sense of ownership and responsibility for quality.

- Fact-based decision making: Decisions are based on data analysis, customer feedback, and performance metrics, rather than intuition or guesswork.

- Integrated systems perspective on processes: TQM considers the interdependencies between different processes and aims to optimize the entire system for maximum efficiency.

TQM's effectiveness is well-documented. Toyota's legendary rise to becoming a quality leader in automotive manufacturing is largely attributed to their embrace of TQM principles. Similarly, Xerox utilized TQM to regain market share in the 1980s, while Florida Power & Light's implementation of TQM led them to win the prestigious Deming Prize. Phillips Semiconductor also achieved significant results, reducing defect rates by an impressive 94% through TQM.

While the benefits are substantial, implementing TQM is not without its challenges. It requires a significant shift in organizational culture and a strong commitment from leadership. Results may take time to materialize, and measuring the return on investment directly can be difficult. Sustained effort is crucial to maintaining momentum and achieving long-term success.

Pros:

- Creates a quality-focused organizational culture

- Improves customer satisfaction and loyalty

- Reduces waste and operational costs over time

- Enhances employee morale and engagement

- Provides a holistic framework for quality improvement

Cons:

- Results may take longer to achieve than other methodologies

- Requires significant cultural change throughout the organization

- Success depends heavily on leadership commitment

- Can be challenging to measure ROI directly

- Requires sustained effort to maintain momentum

Tips for Implementing TQM:

- Obtain visible commitment from top management.

- Provide comprehensive quality training at all levels.

- Establish cross-functional quality improvement teams.

- Implement effective measurement systems to track progress.

- Recognize and reward quality improvements and innovations.

TQM deserves its place on this list because it provides a comprehensive and sustainable approach to improve operational efficiency. By embedding quality into the fabric of the organization, TQM drives not just incremental improvements, but a fundamental shift towards a culture of excellence. This ultimately translates to improved customer satisfaction, reduced costs, and enhanced competitiveness. Learn more about Total Quality Management (TQM) This resource, while focused on project prioritization, can offer valuable insights into decision-making processes within a TQM framework. The principles of prioritization and strategic planning are crucial for effectively implementing TQM initiatives.

5. Value Stream Mapping: A Powerful Tool to Improve Operational Efficiency

Value Stream Mapping (VSM) is a lean management technique that visually represents the entire process flow required to deliver a product or service to a customer. It's a powerful tool to improve operational efficiency by pinpointing bottlenecks, reducing waste, and streamlining operations. Unlike traditional process mapping, which often focuses on individual departments, VSM takes a holistic view, tracking the flow of materials and information from the initial supplier all the way to the end customer. This broader perspective makes it invaluable for identifying hidden inefficiencies and understanding how different parts of a process interact. This makes VSM deserve its place on this list as a highly effective method for optimizing processes and achieving significant efficiency gains.

How Value Stream Mapping Works:

VSM involves creating two key diagrams: a "current state" map and a "future state" map. The current state map depicts the existing process, including all steps, cycle times, lead times, and inventory levels. This detailed visualization reveals non-value-adding activities, redundancies, and areas for improvement. The future state map then outlines the desired, optimized process, incorporating the identified improvements. This two-stage approach provides a clear roadmap for implementing changes and achieving specific efficiency goals.

Key Features and Benefits:

VSM offers several key features that contribute to its effectiveness in improving operational efficiency:

- Visual Representation: The visual nature of VSM makes it easy to understand complex processes and communicate improvement opportunities across teams.

- Value-Added/Non-Value-Added Identification: VSM clearly distinguishes between activities that add value for the customer and those that don't, allowing for targeted waste reduction.

- Cycle Time/Lead Time/Takt Time Analysis: These metrics help identify bottlenecks and optimize process flow for faster delivery and reduced lead times.

- Holistic Perspective: VSM transcends departmental boundaries, promoting a collaborative approach to process improvement.

- Customer Focus: By mapping the entire process from supplier to customer, VSM ensures that improvements directly benefit the customer experience.

Pros and Cons of Value Stream Mapping:

Pros:

- Provides a holistic view of entire processes.

- Creates a common language for process discussion.

- Helps identify hidden waste and non-value-adding steps.

- Facilitates prioritization of improvement efforts.

- Connects process improvements to customer requirements.

Cons:

- Can be time-consuming to create comprehensive maps.

- May require significant data collection and validation.

- Risk of creating overly complex maps that are difficult to understand.

- Effectiveness depends on accurate data and honest assessment.

- Requires regular updates as processes change.

Examples of Successful Implementation:

Several organizations have leveraged VSM to significantly improve operational efficiency:

- Boeing: Reduced aircraft assembly time by 25% through value stream mapping.

- Starbucks: Optimized store operations by mapping customer service flows.

- Intel: Reduced manufacturing cycle time by 70% using value stream analysis.

- Mayo Clinic: Improved patient flow and reduced wait times through process mapping.

Actionable Tips for Using Value Stream Mapping:

- Form a cross-functional team: Include representatives from all departments involved in the process to ensure diverse perspectives.

- Walk the process: Physically observe the process flow to validate the information gathered and identify hidden bottlenecks.

- Focus on one product family or service line at a time: Starting with a smaller scope can make the mapping process more manageable.

- Use standard symbols: This ensures consistency and understanding across the team.

- Update maps regularly: Processes evolve, so it's important to keep the maps current to reflect any changes.

When and Why to Use Value Stream Mapping:

VSM is particularly beneficial when:

- Lead times are excessive: VSM can help identify bottlenecks and optimize flow to reduce lead times.

- Waste is prevalent: VSM helps pinpoint non-value-adding activities and eliminate waste.

- Communication breakdowns occur between departments: VSM fosters a common understanding of the entire process and promotes collaboration.

- Customer satisfaction is low: VSM helps connect process improvements to customer requirements, leading to enhanced customer experiences.

Value stream mapping is a proven methodology for achieving significant improvements in operational efficiency. By visualizing the entire value stream, organizations can identify and eliminate waste, optimize processes, and deliver greater value to their customers.

Popularized by Mike Rother and John Shook (authors of 'Learning to See'), James Womack (founder of Lean Enterprise Institute), Toyota (as part of their Toyota Production System), and the Lean Enterprise Institute, Value Stream Mapping is a vital tool for any organization striving to improve operational efficiency.

6. Agile Project Management

Agile project management is a powerful methodology that can significantly improve operational efficiency. It's an iterative approach that emphasizes flexibility, collaboration, and continuous improvement. Instead of a rigid, sequential process like the traditional waterfall method, Agile breaks projects down into smaller, manageable chunks called "sprints" or "iterations." Each sprint focuses on delivering a working increment of the product or service, allowing for regular feedback and adaptation to changing requirements. This iterative process makes Agile particularly valuable in today's dynamic business environment.

Agile thrives on cross-functional, self-organizing teams that collaborate closely throughout the project lifecycle. Daily stand-up meetings facilitate communication and coordination, while continuous feedback loops ensure the project stays aligned with customer needs. This approach fosters transparency and allows teams to respond quickly to changes, ultimately improving operational efficiency by reducing wasted time and resources. Learn more about Agile Project Management

Features of Agile Project Management:

- Iterative and incremental development cycles: Work is delivered in small, manageable increments.

- Cross-functional, self-organizing teams: Teams are empowered to manage their own work.

- Time-boxed sprints or iterations: Each iteration has a fixed timeframe.

- Daily stand-up meetings for coordination: Brief daily meetings keep everyone on the same page.

- Continuous customer feedback integration: Feedback is gathered and incorporated throughout the project.

Pros:

- Adaptability: Quickly adjusts to changing requirements or market conditions.

- Faster Delivery: Delivers usable products/services earlier and more frequently.

- Improved Visibility: Offers greater transparency into project progress.

- Reduced Risk: Regular testing and feedback minimize potential problems.

- Enhanced Collaboration: Fosters better communication and teamwork.

Cons:

- Implementation Challenges: Can be difficult to implement in traditional or highly regulated environments.

- Resistance to Change: May face resistance from teams used to waterfall methods.

- Stakeholder Involvement: Requires active and ongoing stakeholder participation.

- Predictability: Long-term timelines and budgets can be difficult to estimate initially.

- Scope Creep: Requires careful backlog management to prevent scope creep.

Examples of Successful Agile Implementation:

- Spotify: Their "squad model" revolutionized how they organize development teams, fostering autonomy and innovation.

- Microsoft: Successfully transitioned to Agile practices across their vast development organization.

- NPR: Used Agile to redesign their digital platform, achieving a remarkable 60% reduction in development time.

- John Deere: Implemented Agile in product development, resulting in a 20% reduction in time-to-market.

Tips for Implementing Agile:

- Start Small: Begin with a pilot project to gain experience and build confidence.

- Invest in Training: Provide comprehensive Agile training for all team members and stakeholders.

- Define Roles: Clearly establish roles and responsibilities within Agile teams.

- Visualize Progress: Utilize visual management tools like Kanban boards and burndown charts.

- Continuous Improvement: Hold regular retrospectives to reflect on the process and identify areas for improvement.

Agile project management deserves its place on this list because it provides a structured yet flexible framework for managing projects of all sizes. Its emphasis on customer collaboration, iterative development, and continuous improvement directly contributes to improved operational efficiency, making it an invaluable asset for entrepreneurs, business professionals, teachers, and students alike. By embracing Agile principles, organizations can streamline their processes, respond effectively to change, and deliver high-quality products and services that meet evolving customer needs.

7. Kaizen (Continuous Improvement)

Kaizen, a Japanese term meaning "change for better," is a powerful philosophy for improving operational efficiency. It focuses on implementing small, incremental changes continuously rather than relying on large-scale, disruptive overhauls. This approach fosters a culture of ongoing improvement, empowering employees at all levels to contribute to enhancing processes, equipment, and the overall work environment. By making small, manageable adjustments regularly, organizations can achieve significant gains in efficiency over time. This makes Kaizen a valuable tool for anyone looking to improve operational efficiency, from entrepreneurs and business professionals to teachers and students managing projects or workflows.

How Kaizen Works:

The core principle of Kaizen is the elimination of waste (muda) in all its forms. This includes wasted time, materials, motion, and even human potential. Instead of searching for large, dramatic improvements, Kaizen encourages everyone within the organization – from the CEO to frontline staff – to identify and address small inefficiencies in their daily work. These improvements are implemented through a cyclical process, often using the PDCA (Plan-Do-Check-Act) cycle: plan a change, implement it, check the results, and then act on those findings to standardize and further improve the process. This creates a feedback loop that ensures continuous improvement and adaptation.

Features and Benefits:

- Focus on small, incremental improvements: Reduces disruption and resistance to change.

- All-employee involvement: Taps into the collective wisdom and experience of the entire organization.

- Elimination of waste: Streamlines processes and reduces costs.

- Standardization of processes: Creates consistency and predictability, reducing errors and variability.

- PDCA cycle: Ensures that improvements are data-driven and sustainable.

Examples of Kaizen Success:

Numerous organizations have demonstrated the power of Kaizen to improve operational efficiency. Toyota, a pioneer in Kaizen implementation, reportedly receives over 1 million improvement suggestions from employees annually. Other notable examples include Canon reducing their product development cycle by 50% and Lockheed Martin saving $225 million by implementing employee-suggested improvements. Even the Mayo Clinic has utilized Kaizen principles, improving patient scheduling processes to reduce wait times by an impressive 31%.

Actionable Tips for Implementing Kaizen:

- Create a formal system for collecting improvement ideas: This could be a suggestion box, an online portal, or regular team meetings.

- Provide prompt feedback on all suggestions: This demonstrates that employee input is valued and encourages continued participation.

- Implement a recognition system for valuable improvements: Recognize and reward employees who contribute to improving operational efficiency.

- Train managers to be coaches rather than controllers: Empower employees to take ownership of their work and drive improvement initiatives.

- Set aside dedicated time for improvement activities: Integrate Kaizen into the regular work schedule to ensure ongoing focus.

Pros and Cons:

Pros:

- Low cost of implementation compared to large-scale transformations.

- Creates a culture of continuous improvement.

- Empowers employees at all levels.

- Reduces resistance to change through small steps.

- Cumulative impact can be substantial over time.

Cons:

- Progress may seem slow compared to more radical approaches.

- Requires consistent leadership support to be sustained.

- May face cultural resistance in organizations accustomed to the status quo.

- Can be challenging to track and measure all small improvements.

- Maintaining momentum over the long term requires dedication.

When and Why to Use Kaizen:

Kaizen is ideal for organizations seeking to create a culture of continuous improvement and optimize existing processes. It’s a particularly effective approach when:

- Resources for large-scale change are limited.

- Employee engagement and buy-in are crucial.

- The goal is to build a sustainable system for ongoing improvement.

Learn more about Kaizen (Continuous Improvement)

Kaizen deserves its place on this list because it provides a practical and sustainable framework for improving operational efficiency. By focusing on small, incremental changes and empowering employees, organizations can achieve significant and lasting improvements to their processes, ultimately enhancing productivity, reducing costs, and creating a more engaged workforce.

8. Business Process Reengineering (BPR)

Business Process Reengineering (BPR) is a powerful approach to dramatically improve operational efficiency. It involves a fundamental rethinking and radical redesign of core business processes, rather than incremental improvements, to achieve breakthrough performance gains in areas like productivity, cycle times, and quality. This method deserves a place on this list because it offers the potential for substantial and rapid improvements, particularly for organizations struggling with outdated processes hindering their competitiveness. BPR isn't just about tweaking existing workflows; it's about throwing out the old rule book and creating entirely new ways of working.

How BPR Works:

BPR starts with a clean slate, questioning existing assumptions about how work should be done. It focuses on re-engineering entire processes end-to-end, often leveraging technology to enable new ways of working. This can involve reorganizing people, jobs, and workflows, aligning them with the redesigned process. The approach is inherently customer-focused, aiming to design processes that directly address customer needs and deliver value efficiently.

Key Features of BPR:

- Fundamental Rethinking: Challenges the status quo and encourages innovative thinking about how work can be done.

- Radical Redesign: Focuses on significant changes, not incremental adjustments.

- Process-Centered: Prioritizes processes over traditional departmental or functional structures.

- Technology-Enabled: Utilizes technology as a key enabler of process transformation.

- Customer-Focused: Designs processes with the customer's needs and experience as the primary drivers.

Examples of Successful BPR Implementation:

Several companies have achieved significant improvements through BPR:

- Ford Motor Company: Reduced accounts payable headcount by 75% by reengineering their invoice processing.

- Procter & Gamble: Reorganized their product development process, cutting time-to-market by 50%.

- IBM Credit: Streamlined their credit approval process, reducing processing time from 7 days to 4 hours.

- Hallmark: Shortened their product development cycle from 3 years to 1 year.

These examples demonstrate the potential of BPR to deliver substantial improvements in operational efficiency.

Pros and Cons of BPR:

While BPR can be transformative, it's essential to be aware of both its advantages and disadvantages.

Pros:

- Dramatic Performance Improvements: Can deliver significant and rapid gains in efficiency, productivity, and quality.

- Eliminates Outdated Processes: Removes legacy systems and thinking that hinder performance.

- Technological Innovation: Creates opportunities to leverage new technologies and automate processes.

- Customer Focus: Aligns processes directly with customer needs, enhancing satisfaction and loyalty.

- Increased Competitiveness: Transforms organizations to be more agile and responsive to market changes.

Cons:

- High Risk of Failure: BPR initiatives can be complex and challenging to implement, with a high failure rate if not managed effectively.

- Significant Disruption: Can cause considerable disruption to existing workflows and organizational structures.

- Resistance to Change: Often encounters resistance from employees accustomed to traditional ways of working.

- Substantial Investment: Requires significant investment in time, resources, and technology.

- Potential Job Losses: May result in job losses or significant role changes due to process redesign and automation.

Actionable Tips for Implementing BPR:

- Secure Executive Sponsorship: Gain strong support from senior management to ensure commitment and resource allocation.

- Process-Centric Approach: Focus on reengineering processes, not departments or functions.

- Customer Involvement: Involve customers in the redesign process to understand their needs and expectations.

- Change Management Plan: Develop a comprehensive change management plan to address employee concerns and facilitate a smooth transition.

- Cross-Functional Teams: Create cross-functional teams to lead reengineering efforts and ensure diverse perspectives.

When and Why to Use BPR:

BPR is most appropriate when organizations are facing significant performance challenges, outdated processes, or disruptive market changes. It's a radical approach best suited for situations where incremental improvements are insufficient to achieve desired outcomes. BPR should be considered when a fundamental shift in how work is done is necessary to improve operational efficiency and gain a competitive edge.

Operational Efficiency Strategies Comparison

| Strategy | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Lean Management | Medium to High – requires cultural change and training | Moderate – investment in training and continuous improvement | Waste reduction, improved quality, faster delivery, engaged workforce | Organizations seeking operational excellence and waste elimination | Continuous improvement culture, cost reduction, quality boost |

| Six Sigma | High – structured DMAIC process with extensive training | High – statistical tools, certification, and software needed | Reduced defects, process variation control, measurable financial ROI | Complex processes needing defect reduction and statistical control | Data-driven problem solving, strong ROI focus |

| Business Process Automation (BPA) | Medium – may require process redesign and technology integration | High – technology investment and process redesign | Significant efficiency gains, error reduction, consistent process | High-volume repetitive tasks for automation | Speeds execution, reduces errors, frees resources |

| Total Quality Management (TQM) | Medium to High – organization-wide cultural change | Moderate – leadership commitment and training needed | Long-term quality improvement, customer satisfaction, waste reduction | Organizations aiming for holistic, continuous quality improvement | Organization-wide quality focus, improved morale |

| Value Stream Mapping | Medium – requires detailed data gathering and cross-team effort | Low to Moderate – depends on mapping tools and time invested | Clear process visibility, waste identification, prioritized improvements | Process improvement initiatives and Lean implementations | Holistic process view, waste identification, common language |

| Agile Project Management | Medium – requires mindset shift and stakeholder involvement | Moderate – training and tools for iterative workflows | Faster delivery, adaptability, enhanced team collaboration | Projects with changing requirements and need for frequent feedback | Early product delivery, flexibility, improved transparency |

| Kaizen (Continuous Improvement) | Low to Medium – incremental changes requiring leadership support | Low – mainly cultural and time investment | Gradual improvements, engaged workforce, sustained culture of change | Organizations focusing on continuous small-scale improvements | Low cost, employee empowerment, long-term impact |

| Business Process Reengineering (BPR) | High – radical redesign with significant disruption | High – investment in change management, technology, and people | Dramatic productivity and cycle time improvements, competitive advantage | Organizations needing breakthrough performance and business transformation | Rapid significant improvements, innovation enabler |

Ready to Transform Your Operations?

Improving operational efficiency is a continuous pursuit that yields significant rewards. We've explored eight key strategies—Lean Management, Six Sigma, Business Process Automation (BPA), Total Quality Management (TQM), Value Stream Mapping, Agile Project Management, Kaizen, and Business Process Reengineering (BPR)—each offering unique approaches to streamline processes and maximize resources. Mastering these concepts is crucial for any organization striving to enhance productivity, minimize waste, and achieve sustainable growth. From eliminating bottlenecks with Lean principles to fostering a culture of continuous improvement with Kaizen, these methodologies provide a robust toolkit for optimizing every facet of your operations. For practical tips on streamlining processes and boosting productivity, check out this helpful resource on how to improve operational efficiency.

Implementing these strategies effectively, however, requires careful planning and execution. The key takeaway is that lasting improvements come from consistent effort and a commitment to adapting and evolving your approaches. By embracing these methodologies, you're not just improving efficiency; you're building a more resilient, adaptable, and ultimately more successful organization, ready to thrive in 2026 and beyond.

Ready to take your operational efficiency to the next level and put these principles into action? The Boss Personal Planner can be an invaluable tool for implementing these strategies, providing a structured framework for managing projects, tracking progress, and maintaining focus on continuous improvement. Invest in your operational excellence today and see the transformative impact it has on your organization.